Yakagadziriswa Speed Screw Air compressor

Tsananguro yechigadzirwa

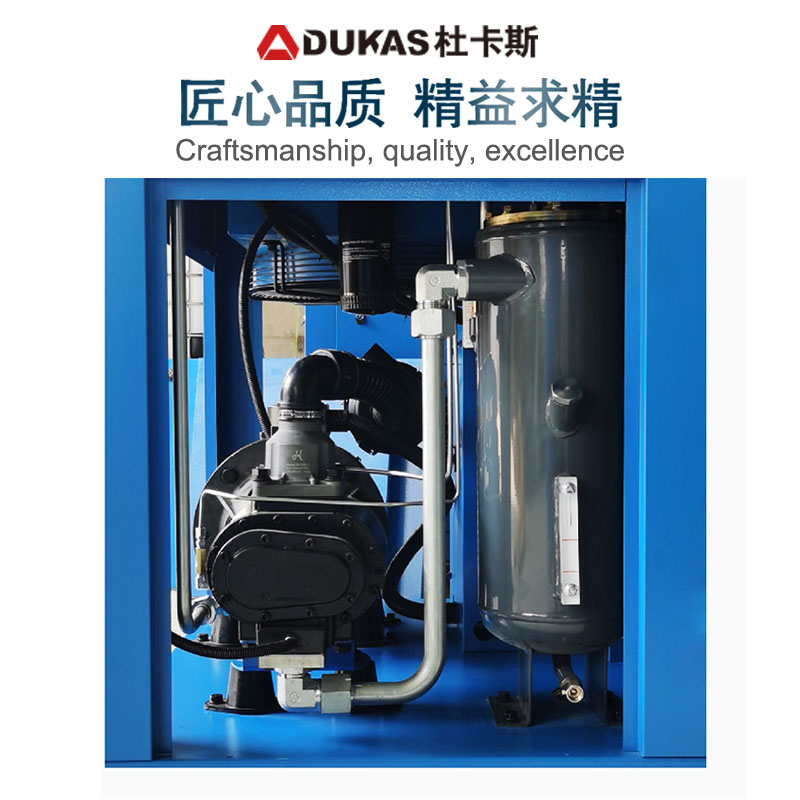

Controller

Anotambira iyo International Pamusoro-Chikamu-Chizvarwa Asymmetric Wire Kupera, Anomirira Kuwana Kunoita Scetrescing Scomputer Kuwedzeredza-kudzvanywa, yakakwira mhepo chimiro uye iyo axial Air inlet dhizaini.

Inverter

Iyo chiyero chakashongedzerwa neyakakwira frequency placents, zvinobudirira kudzora iyo frequency converenter uye iyo yekunze yemagineti munda yakaoma yakaoma.

Kutonhora

Iyo yekupisa yekudziya inoshandisa yakakwirira-mhando zvigadzirwa zvemukati uye zvakasarudzika zvemukati chiteshi, chinowedzera iyo yekupisa nzvimbo yekutsinhana uye inogona kunyatsoisa kupisa kwemhepo compressor.

Mafuta efaira

Inogamuchira yakakwira-density firita zvinhu, iyo nzvimbo inobatwa ne nano-electroplating.

Oiri inoparadzanisa

Iyo yakakwira-yemhando yemhepo yekuparadzaniswa kwemhepo uye gasi-yemvura extring element matatu emhepo yekuparadzanisa kwemhepo yekupatsanurwa ye-oiri yekuchengetedza mairi

Mhepo magumo

Anotambira iyo International Pamusoro-Chikamu-Chizvarwa Asymmetric Wire Kupera, Anomirira Kuwana Kunoita Scetrescing Scomputer Kuwedzeredza-kudzvanywa, yakakwira mhepo chimiro uye iyo axial Air inlet dhizaini.

Fan

Iyo fan inoshandisa yakakura fan gadziriro yekukurudzira zvinobudirira kusimudzira kupisa kwe fan yekusagadzikana kwemhedzisiro inoenderana neyakajairika yemukati momukati dhizaini yekuenderana nemamiriro ezvinhu eHarsh.

Mota

Mota inoshandisa motor-ekuita motors yemhando dzinozivikanwa kwazvo. Chisingaperi maget synchronous motors (pm motors) shandisa yakakwirira-performance ndfebatendes

Intha Valve

Kuve neNyika Yakakurumbira Yemhando yemhando yemhepo Intake Valve, inogona kugadzirisa ongororo iyo 0-100% maererano nezvinodiwa zvemhepo huwandu hwemhepo. Inovimbisa kurasikirwa kukuru kwekumanikidza, kugadzikana chiito uye hupenyu hwakareba zvakadzama zvakaderedzwa mari yekushandisa.

Mhepo Filter

Kutora dhizaini neguruva repamusoro kubata kugona uye kuderera kuyerera kuramba, izvo zvinogona kusefa zvidiki zvidiki zvakagadziriswa mumhepo. Iyo guruva kubvisa mari inogona kusvika 99.5%, ichiva yakajairika kushanda kwezvinhu zvehurongwa uye kuwedzera hupenyu hwebasa.

Timu nevatengi

Muna May 2015, mutengi weAustralia anouya kuzoshanyira Dukas, tinovapa icho chibvumirano chakazara.

MunaSeptember 2016, Mutengi weIndia anouya kuzoshanyira Dukas, isu tinonina chibvumirano chekubatana pagore.

Muna Gumiguru 2016, mutengi weTurkey akauya kuzoshanyira Dukas, tinoitawo chibvumirano chekutanga uye tenderera kushandira pamwe kusvika zvino.

Muna June 2017, mutengi weBritish anouya kuzoshanyira Dukas, ongorora compressor yavakaraira uye ikaisa mutemo wegore rimwe mushure mekushanya.

MunaNovember 2018, mutengi weIsrael anouya kuzoshanyira Dukas, ongorora fekitari yedu uye isu tinodzidzisa mainjiniya avo.

MunaJuly 2018, Bangladeshi mutengi anouya kuzoshanyira Dukas, anoidza maitiro edu ekumanikidza uye isu tinoita chibvumirano mushure mekuedzwa kwakabudirira.

Zvekubvunza nezve zvigadzirwa zvedu kana pricelist, ndapota siya yako email kwatiri uye isu tichave tichikurukurirana mukati memaawa makumi maviri nemana.

Zvakanakira Dukas Screw Air compressor

1. Ngwangwara Kudzora System ine Big kubata screen

Kuratidzwa zvakananga kwekuratidzira tembiricha uye kumanikidzwa, kushanda frequency, zvazvino, simba, kushanda nguva yekutarisa kwekudzvinyirira uye kumanikidzwa, zvazvino, zvinowanzoitika.

2. Wide inoshanda frequency levence kuti uchengetedze simba

Kupfuura kushandurwa kubva ku5% kusvika ku100%

3. Diki Rinotanga -U Kubata Chengetedza Fekitori Simba Simba

Shandisa frequency kutendeuka kwemagariro zvachose

4. Hunhu Hunhu Clopy Dhizaina Easy kuchengetedza

Iyo compressor inoratidza kuvakwa kwakasimba saka kunovakira kwekupedzisira. Izvo zvikamu zvese zvemhepo compressor zvinogadzirwa nemhando yemhando iyo ichagara kwemakore.

Kunze kwekuzadza iyo lubricant, iwe unongoda kuita mamwe ekugadzirisa mhepo yekugadzirisa maitiro ekugadzirisa maitiro.

5. Chizvarwa chechizvarwa chakapfuura chakasimba chengetedza inverter chengetedza chaiyo yekushanda maitiro

Kudzvinyirirwa Kwemhepo Kugadziriswa, kudzvinyirirwa kwemhepo kwakanyatso kudzorwa mukati me 0.01mpa.constant tembiricha yekumanikidza. Kugadzirwa uye Mutengi System Mhepo Inodiwa Nguva Dzese Kuchengeta Zvakafanana.

6. Suppirwa wakachena wakamanikidzwa mweya

Zvishandiso zvinoshanda nemhepo yakamanikidzwa kazhinji inotarisa pakumanikidzwa kwemhepo, asi vanhu vazhinji vanofuratira kuti mukudzvinyirira kwemhepo yakamanikidzwa, kuchena kwayo kunokanganisa hupenyu hwemidziyo. Sekushandiswa kweshandisirwo yemagetsi optics michina, kunge laser cutting michina, mavara mavara uye zvichingodaro. Isu tinoshandisa yakakwirira performance oiri inoparadzanisa uye inotonhorera system yekuona kuti inopa iyo yakachena yakamanikidzwa kumhepo kumidziyo yako.

7. Host Holdntyy Enzanisa kune mamwe makambani

Yedu Waranti ndeye makore maviri emuchina wakakwana, enzanisa nemamwe makambani, zvakanyanya ivo vari kupa gore ra 1 gore. Nemakore makumi maviri ruzivo tine chivimbo chekuita zvakanaka kune vatengi vedu pasi rese.

Zvinyorwa

PM vsd screw Air compressor rondedzero 7.5KW-45KW

| Modhi | DKK-7.5V | DKK-11V | DKK-15V | DKK-18.5V | DKS-22V | DKK-30V | DKK-37V | DKK-45V | |

| Mota | Simba(Kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 |

| Horsepower (PS) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | |

| Mhepo yekufambisa /Kushanda Kumanikidza (M3 / Min. / Mpa) | 1.2 / 0.7 | 1.9 / 0.7 | 2.5 / 0.7 | 3.2 / 0.7 | 3.8 / 0.7 | 5.3 / 0.7 | 6.8 / 0.7 | 7.4 / 0.7 | |

| 1.1 / 0.8 | 1.7 / 0.8 | 23 / 0.8 | 3.0 / 0.8 | 3.6 / 0.8 | 5.0 / 0.8 | 6.2 / 0.8 | 7.0 / 0.8 | ||

| 0.9 / 1.0 | 1.6 / 1.0 | 2.1 / 1.0 | 2.7 / 1.0 | 3.2 / 1.0 | 4.5 / 1.0 | 5.6 / 1.0 | 6.2 / 1.0 | ||

| 0.8 / 1.2 | 1.4 / 1.2 | 1.9 / 1.2 | 2.4 / 1.2 | 2.7 / 1,2 | 4.0 / 1,2 | 5.0 / 1,2 | 5.6 / 1.2 | ||

| Mhepo Inobuda Diamita | DN20 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | |

| Lubricating vhoriyamu (l) | 10 | 16 | 16 | 18 | 18 | 30 | 30 | 30 | |

| Ruzha ruzha db (a) | 60 ± 2 | 62 ± 2 | 62 ± 2 | 64 ± 2 | 64 ± 2 | 66 ± 2 | 66 ± 2 | 66 ± 2 | |

| Nzira yekutyairwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | |

| Kutanga nzira | Pm vsd | Pm vsd | Pm vsd | Pm vsd | Pm vsd | Pm vsd | Pm vsd | Pm vsd | |

| Uremu (kg) | 220 | 350 | 360 | 510 | 510 | 650 | 700 | 780 | |

| Kuwedzera Zvidimbu | Kureba (mm) | 900 | 1100 | 1100 | 1200 | 1200 | 1460 | 1460 | 1460 |

| upamhi (mm) | 680 | 730 | 730 | 880 | 880 | 980 | 980 | 980 | |

| Kureba (mm) | 800 | 980 | 980 | 1080 | 1080 | 1230 | 1230 | 1230 | |

PM vsd screw Air compressor rondedzero 55KW-132KW

| Modhi | DKK-55V | DKK-75V | DKK-90V | DKS-110V | DKK-132V | ||

| Mota | Simba (KW) | 55 | 75 | 90 | 110 | 132 | |

| Horsepower (PS) | 75 | 100 | 125 | 150 | 175 | ||

| Mhepo yekufambisa / yekushanda kumanikidzwa (M3/ Min / mpa) | 10.0 / 0.7 | 13.4 / 0.7 | 16.2 / 0.7 | 21.0 / 0.7 | 24.5 / 0.7 | ||

| 9.2 / 0.8 | 12.6 / .0.8 | 15.0 / 0.8 | 19.8 / 0.8 | 23.2 / 0.8 | |||

| 8.5 / 1.0 | 11.2 / 1.0 | 13.8 / 1.0 | 17.4 / 1.0 | 20.5 / 1,0 | |||

| 7.6 / 1.2 | 10.0 / 1,2 | 12.3 / 1,2 | 14.8 / 1.2 | 17.4 / 1.2 | |||

| Mhepo Inobuda Diamita | DN50 | DN50 | DN50 | DN65 | DN65 | ||

| Lubricating vhoriyamu (l) | 65 | 65 | 72 | 90 | 90 | ||

| Ruzha ruzha db (a) | 68 ± 2 | 68 ± 2 | 70 ± 2 | 70 ± 2 | 70 ± 2 | ||

| Nzira yekutyairwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | Direct inotungamirwa | ||

| Kutanga nzira | Pm vsd | Pm vsd | Pm vsd | Pm vsd | Pm vsd | ||

| Uremu (kg) | 1250 | 1350 | 1950 | 2200 | 2500 | ||

| Kuwedzera Zvidimbu | Kureba (mm) | 1750 | 1750 | 2450 | 2450 | 2450 | |

| upamhi (mm) | 1280 | 1280 | 1660 | 1660 | 1660 | ||

| Kureba (mm) | 1590 | 1590 | 1700 | 1700 | 1700 | ||

Zvigadzirwa Zvikamu

-

E-mail

E-mail

-

Foni &

Whatsapp -

Pamusoro